Vertical immersed pumps

With a hydraulic system consisting of a single-stage or multistage centrifugal pump, our vertical immersed pumps are used wherever pumping under water is called for, but it is necessary to ensure that the motor never comes into contact with the medium, for instance for hot liquids or media that outgas flammable substances. The ideal applications of OSNA’s vertical immersed pumps include moving hot water in industrial laundries as well as waste water treatment in industrial plants and sewage treatment plants. Depending on the medium and its temperature range, we use various grades of steel up to highly resistant duplex steel in the construction of our vertical immersed pumps.

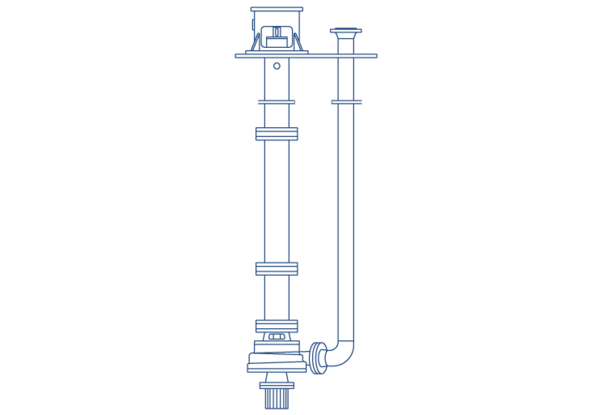

NMVN, GVN

Vertical immersed pump for installation into a tank

Performance data

Q max. 500 m³/h (2.200 USGPM)

H max. 400 m (1.312 ft)

Applications

Wherever a conventional submerged pump is not desired or may not be used to design reasons (e.g. high temperature oft he medium). Fort he pumping of clean water, boiler feeding water, condensate and cooling water up to +140 °C (284 °F)

Design

Vertical immersed pump for installation into a tank. The hydraulic elements originate from our programme of horizontal centrifugal pumps (e.g. NMV or GV). The pumps will be mounted on a tank using a supporting plate, constructed as tank cover. The supporting plate can also be constructed as gas-tight round flange according to DIN, ANSI or other standards. Driver and shaft seal of the pump are located above the tank. The pump part is immersed into the tank and thereby into the medium. A line shaft pipe connects the pump to the cover plate. This line shaft pipe can consist of either one or several segments, being constructed with intermediate pipes and shafts, bearings and shaft couplings. When using the hydraulic part of an end suction pump, discharge pipe and line shaft pipe are separate components. In multistage pumps, the line shaft pipe also serves as discharge pipe.

Materials

As required according to the pumping medium, such as cast iron, cast steel or cast stainless steel. Special materials on request

print

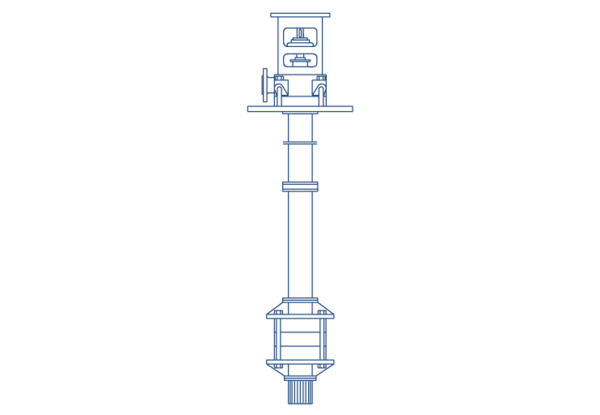

SVN, SKVN

Vertical immersed pump for installation into a tank

Performance data

Q max. 600 m³/h (2.641 USGPM)

H max. 90 m (295 ft)

Applications

Wherever a conventional submerged pump is not desired or may not be used to design reasons (e.g. high temperature oft he medium). Fort he pumping of clean water, boiler feeding water, condensate and cooling water up to +140 °C (284 °F)

Design

Vertical immersed pump for installation into a tank. The hydraulic elements originate from our programme of horizontal centrifugal pumps (e.g. SKT). The pumps will be mounted on a tank using a supporting plate, constructed as tank cover. The supporting plate can also be constructed as gas-tight round flange according to DIN, ANSI or other standards. Driver and shaft seal of the pump are located above the tank. The pump part is immersed into the tank and thereby into the medium. A line shaft pipe connects the pump to the cover plate. This line shaft pipe can consist of either one or several segments, being constructed with intermediate pipes and shafts, bearings and shaft couplings. When using the hydraulic part of an end suction pump, discharge pipe and line shaft pipe are separate components. In multistage pumps, the line shaft pipe also serves as discharge pipe.

Materials

As required according to the pumping medium, such as cast iron, cast steel or cast stainless steel. Special materials on request

print